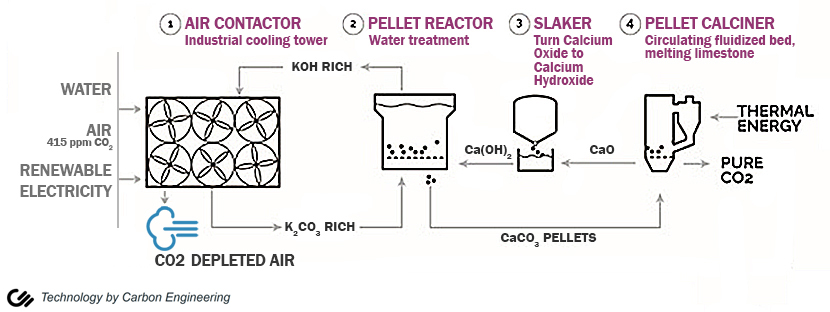

The CO2 contained in this carbonate solution is then put through a series of chemical processes to increase its concentration, purify and compress it, so it can be delivered in gas form ready for use or storage. This involves separating the salt out from solution into small pellets in a structure called a pellet reactor. These pellets are then heated in the third step, a calciner, in order to release the CO2 in pure gas form. This step also leaves behind processed pellets that are hydrated in a slaker and recycled back within the system to reproduce the original capture chemical.

Direct Air Capture technology, developed by Carbon Engineering, continuously captures CO2 from atmospheric air and delivers it as a purified, compressed gas – using only air, water, and clean electricity as inputs.

Please take a look at the videos below that reveal further information about the Direct Air Capture methodology and the idea behind capturing CO2 from the atmosphere.

[/av_textblock]

[/av_section][av_layout_row border=” min_height_percent=” min_height_pc=’25’ min_height=’0′ color=’main_color’ mobile=’av-flex-cells’ mobile_breaking=” av-desktop-hide=” av-medium-hide=” av-small-hide=” av-mini-hide=” id=” custom_class=” aria_label=” av_element_hidden_in_editor=’0′ av_uid=’av-2cymg7′]

[av_cell_one_third vertical_align=’top’ padding=’5px’ padding_sync=’true’ background=’bg_color’ background_color=’#7bb0e7′ background_gradient_color1=” background_gradient_color2=” background_gradient_direction=’vertical’ src=” attachment=” attachment_size=” background_attachment=’scroll’ background_position=’top left’ background_repeat=’no-repeat’ link=” linktarget=” link_hover=” mobile_display=” custom_class=” av_uid=’av-2acknb’]

[/av_cell_one_third][av_cell_one_third vertical_align=’top’ padding=’5px’ padding_sync=’true’ background=’bg_color’ background_color=’#233857′ background_gradient_color1=” background_gradient_color2=” background_gradient_direction=’vertical’ src=” attachment=” attachment_size=” background_attachment=’scroll’ background_position=’top left’ background_repeat=’no-repeat’ link=” linktarget=” link_hover=” mobile_display=” custom_class=” av_uid=’av-7ieof’]

[/av_cell_one_third][av_cell_one_third vertical_align=’top’ padding=’5px’ padding_sync=’true’ background=’bg_color’ background_color=’#7bb0e7′ background_gradient_color1=” background_gradient_color2=” background_gradient_direction=’vertical’ src=” attachment=” attachment_size=” background_attachment=’scroll’ background_position=’top left’ background_repeat=’no-repeat’ link=” linktarget=” link_hover=” mobile_display=” custom_class=” av_uid=’av-1v6ks7′]

[/av_cell_one_third]

[/av_layout_row]

[av_layout_row border=” min_height_percent=” min_height_pc=’25’ min_height=’0′ color=’main_color’ mobile=’av-flex-cells’ mobile_breaking=” id=” custom_class=” aria_label=” av_element_hidden_in_editor=’0′ av_uid=’av-khny5val’]

[av_cell_one_half vertical_align=’top’ padding=’30px’ padding_sync=’true’ background=’bg_color’ background_color=’#233857′ background_gradient_color1=” background_gradient_color2=” background_gradient_direction=’vertical’ src=” attachment=” attachment_size=” background_attachment=’scroll’ background_position=’top left’ background_repeat=’no-repeat’ link=” linktarget=” link_hover=” mobile_display=” custom_class=” av_uid=’av-khny844r’]

[av_video src=’https://www.youtube.com/watch?v=VtOhPEU8CrA’ mobile_image=” attachment=” attachment_size=” format=’16-9′ width=’16’ height=’9′ conditional_play=” id=” custom_class=” av_uid=’av-kgzqrywr’]

[/av_cell_one_half][av_cell_one_half vertical_align=’top’ padding=’30px’ padding_sync=’true’ background=’bg_color’ background_color=’#95aabf’ background_gradient_color1=” background_gradient_color2=” background_gradient_direction=’vertical’ src=” attachment=” attachment_size=” background_attachment=’scroll’ background_position=’top left’ background_repeat=’no-repeat’ link=” linktarget=” link_hover=” mobile_display=” custom_class=” av_uid=’av-khny98x2′]

[av_video src=’https://www.youtube.com/watch?v=XHX9pmQ6m_s’ mobile_image=” attachment=” attachment_size=” format=’16-9′ width=’16’ height=’9′ conditional_play=” id=” custom_class=” av_uid=’av-kfv1im8e’]

[/av_cell_one_half]

[/av_layout_row]

[av_layout_row border=” min_height_percent=” min_height_pc=’25’ min_height=’0′ color=’main_color’ mobile=’av-flex-cells’ mobile_breaking=” id=” custom_class=” aria_label=” av_element_hidden_in_editor=’0′ av_uid=’av-khny5val’]

[av_cell_one_half vertical_align=’top’ padding=’30px’ padding_sync=’true’ background=’bg_color’ background_color=’#95aabf’ background_gradient_color1=” background_gradient_color2=” background_gradient_direction=’vertical’ src=” attachment=” attachment_size=” background_attachment=’scroll’ background_position=’top left’ background_repeat=’no-repeat’ link=” linktarget=” link_hover=” mobile_display=” custom_class=” av_uid=’av-khnyabll’]

[av_video src=’https://www.youtube.com/watch?v=Mb_8DJF6Hp0′ mobile_image=” attachment=” attachment_size=” format=’16-9′ width=’16’ height=’9′ conditional_play=” id=” custom_class=” av_uid=’av-kgzqrywr’]

[/av_cell_one_half][av_cell_one_half vertical_align=’top’ padding=’30px’ padding_sync=’true’ background=’bg_color’ background_color=’#233857′ background_gradient_color1=” background_gradient_color2=” background_gradient_direction=’vertical’ src=” attachment=” attachment_size=” background_attachment=’scroll’ background_position=’top left’ background_repeat=’no-repeat’ link=” linktarget=” link_hover=” mobile_display=” custom_class=” av_uid=’av-khnyanhx’]

[av_video src=’https://www.youtube.com/watch?v=ZQGGhtguHns’ mobile_image=” attachment=” attachment_size=” format=’16-9′ width=’16’ height=’9′ conditional_play=” id=” custom_class=” av_uid=’av-kfv1im8e’]

[/av_cell_one_half]

[/av_layout_row]

[av_layout_row border=” min_height_percent=” min_height_pc=’25’ min_height=’0′ color=’main_color’ mobile=’av-flex-cells’ mobile_breaking=” av-desktop-hide=” av-medium-hide=” av-small-hide=” av-mini-hide=” id=” custom_class=” aria_label=” av_element_hidden_in_editor=’0′ av_uid=’av-2cymg7′]

[av_cell_one_third vertical_align=’top’ padding=’5px’ padding_sync=’true’ background=’bg_color’ background_color=’#7bb0e7′ background_gradient_color1=” background_gradient_color2=” background_gradient_direction=’vertical’ src=” attachment=” attachment_size=” background_attachment=’scroll’ background_position=’top left’ background_repeat=’no-repeat’ link=” linktarget=” link_hover=” mobile_display=” custom_class=” av_uid=’av-2acknb’]

[/av_cell_one_third][av_cell_one_third vertical_align=’top’ padding=’5px’ padding_sync=’true’ background=’bg_color’ background_color=’#233857′ background_gradient_color1=” background_gradient_color2=” background_gradient_direction=’vertical’ src=” attachment=” attachment_size=” background_attachment=’scroll’ background_position=’top left’ background_repeat=’no-repeat’ link=” linktarget=” link_hover=” mobile_display=” custom_class=” av_uid=’av-7ieof’]

[/av_cell_one_third][av_cell_one_third vertical_align=’top’ padding=’5px’ padding_sync=’true’ background=’bg_color’ background_color=’#7bb0e7′ background_gradient_color1=” background_gradient_color2=” background_gradient_direction=’vertical’ src=” attachment=” attachment_size=” background_attachment=’scroll’ background_position=’top left’ background_repeat=’no-repeat’ link=” linktarget=” link_hover=” mobile_display=” custom_class=” av_uid=’av-1v6ks7′]

[/av_cell_one_third]

[/av_layout_row]